Innovation

Innovative economy

New technical solutions

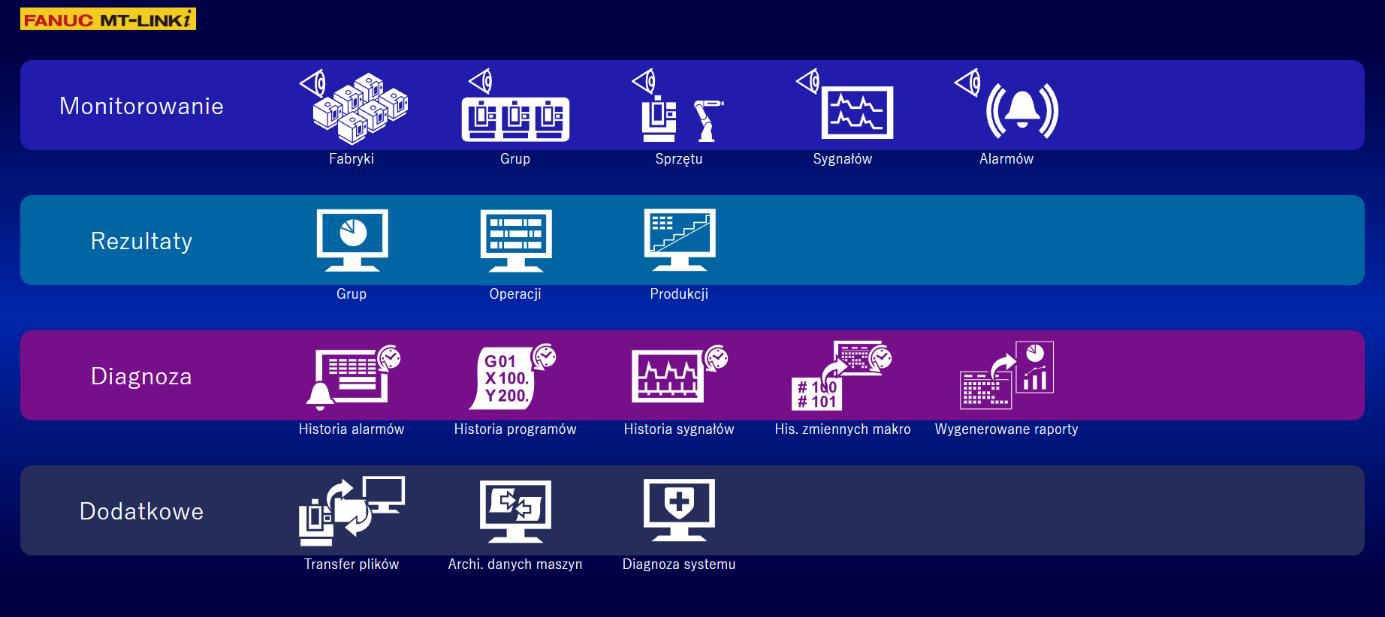

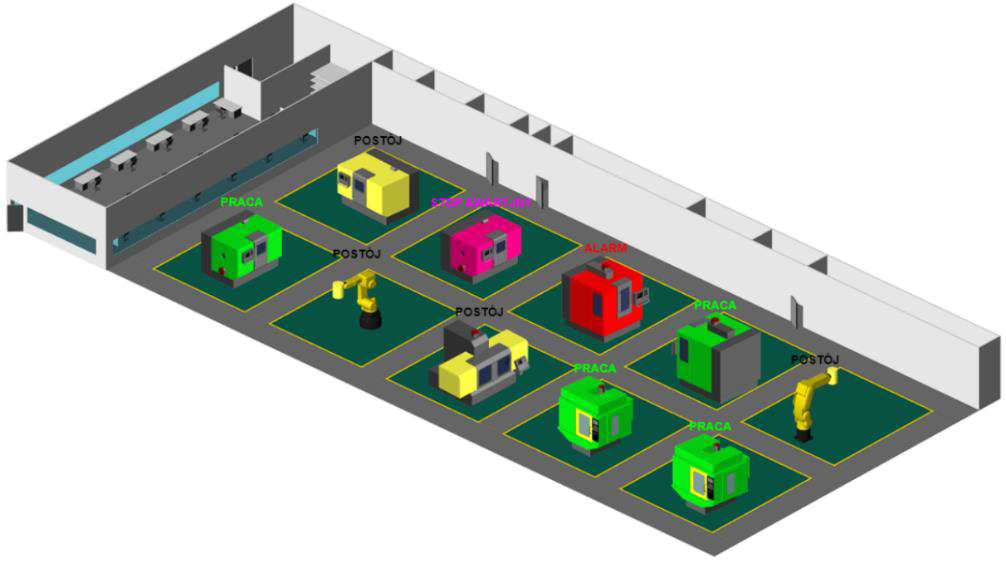

In 2021 Our company has introduced the innovative FANUC MT-LINK system, used to monitor and diagnose machines and devices. It is a system that collects information from machines via LAN in real time and saves it in a database.

Benefits:

➢ A simple way to collect and present a wide range of data from multiple devices'

➢ Greater control over production, which makes it possible to increase productivity by eliminating the "bottlenecks",

➢ Communication with superior MES systems,

➢ Possibility to connect various devices: FANUC control, OPC FANUC control, UA MTConnect, robots.

Siemens NX Software

In order to improve production, we purchased Siemens NX software, for CAM programming.

Benefits:

➢ Collision-free programming – the ability to simulate machining on a computer (e.g. simulation of the tool path, holder or instrument fixing the workpiece) based on the code from the postprocessor, as well as the NC code (written by hand),

➢ Intuitive programming – using a 3D model, macros and templates,

➢ Time saving – allows to program quickly and clearly (up to 50% faster than programming manually or using machine cycles),

➢ Easier updates – the software works perfectly with Siemens Solid Edge, which allows to quickly update workpieces and maintain greater order when archiving.

Innovative solutions in the production of hydraulic cylinders

The development of the company is based on the expansion and improvement of the manufactured products with the use of innovative, less costly manufacturing technologies . This goal is to be served by the continuous development of the Research and Development department, the effects of which are becoming more and more visible. Thanks to our work, we can offer a number of actuator solutions for modern machines and devices. These are among others:

· Cylinders for automatic rotation and alignment of plows.

· Cylinders with mechanical and hydraulic locks in full range of motion.

· Actuators with coasting, constant and progressive braking.

· Actuators with internal, maintenance-free venting.

· Cylinders for tandem operation.

Actuators with linear reading of the distance or position of the end positions of the piston.

Single-acting piston cylinders with a patented sealing system.

Proprietary ERP system

In our company, we have our own ERP system, created by the IT department. This system supports the management of the most important resources and and processes in every area of the company.Starting from production, through the warehouse, sales departments, human resources, supplies, ending with accounting. The entire system is based on a databaseto which each department has access, thanks to which communication between departments is greatly improved..

Benefits:

➢ Central management system based on a database

➢ Fast information flow

➢ Automation of many processes

➢ Access to necessary data from anywhere in the company

Oil purity

Oil purity is important from the point of view of of the service life of the hydraulic system – it is one of the significant factors affecting the loss of usability of such a system. A dirty hydraulic system can cause faster aging of its individual components as well as the oil itself, internal and external leaks, valve adjustment inaccuracies up to a sudden failure of the components of the entire system. Water, that can be found in the oil, causes: corrosion, increased abrasion, accelerated aging of the oil, etc. Among the causes of pollution, impurities from system components are often mentioned, among which hydraulic cylinders play an important role. An increasing number of companies know how important this issue is and are raising their requirements for cleanliness classes. To meet them, based on funds from PARP, we designed and built from scratch a system of filtration and and control of the level of oil purity during tests and we purchased high-class washing equipment. Since we subject each cylinder produced to leak tests we are sure that the products leaving our plant meet the high requirements currently set for cylinders manufacturers.

The aim of the implementation of new technologies is to acquire quality-demanding customers from Polish and abroad..